Discharging wastewater containing organic matter and all other pollutant loads into the soil or receiving environment without treatment is another way of saying "declaring war on nature."

All the chocolates, candies, and similar foods we consume go through many stages from production to packaging, and their ability to emerge from these stages depends on the necessary hygiene being maintained. Waste generation is an unavoidable reality in every production process. To truly "produce" means not to consume while producing, but to ensure sustainability during production. As humans, the more we produce, the more we tend to consume, which is why the concept of sustainability has started to gain new meaning for 21st-century people. Because in this century, we have statistically proven to ourselves that all the resources we thought would never run out will one day be depleted.**Our Greatest Proof: Drought!**Another way to say that the organic matter and all other pollutant loads in wastewater are discharged into the soil or receiving environment without treatment is to say "war is declared on nature." We cannot prevent wastewater formation, but we can take ownership of our wastewater, recover it, and reuse it. This technology has many different integrations. These integrations become apparent according to the answers to questions like "What is the source?" and "How much?" Because the pollutant loads in wastewater generated from each production are not the same. The reason for this is the factors involved in wastewater formation. The wastewater from a textile factory that dyes and washes cannot be expected to be from the same family as the wastewater generated from chocolate production. Therefore, determining the processes to be applied for the treatment and recovery of wastewaters depends on the source of the water.The food manufacturing sector is a sector that uses a large amount of water for hygiene and sanitation purposes, and due to high water usage, wastewater is generated in very different concentrations and amounts. The discharged wastewaters contain high amounts of suspended solids, high organic matter loads, and various chemical forms of nitrogen, phosphorus, and organic matter. Generally, in the food sector, BOD and COD values are 10 or 100 times higher than those of domestic wastewaters.is at a higher level.

Water consumption varies according to the diversity of the produced chocolates. For example, according to data on water consumption and water footprint from a chocolate manufacturing business in the United Kingdom; molded chocolates rank first with a water consumption of 11372 liters/kg, followed by bagged chocolates with 10848 liters/kg in second place, and individually packaged chocolates come in third with 7633 liters/kg. However, most of the wastewater generated is reusable water; that is, green water, and all of it originates from raw materials. The product that causes the most blue water formation, which we refer to as non-reusable water, is the production of bagged chocolate. The main blue water consumption occurs during the packaging stage, followed by that from raw materials and production. In confectionery manufacturing, there is no wastewater formation during the production processes of sugary-sugar-free gum, hard-soft candies, etc. However, wastewater is generated from processes such as washing equipment, sieves, dough kettles, syrup/cooking kettles, and trays. Wastewater from businesses operating in this industry is generally acidic in nature and contains high organic matter, and it can be treated through a two-stage treatment process where anaerobic (oxygen-free) treatment is applied as a pre-treatment.

According to the diversity of production in the food sector, the general sources of wastewater pollution are as follows;

- Washing, soaking, treating raw materials with water, and cleaning containers

- Transporting waste or raw materials or floating them in channels

- Cleaning areas where processes are located, process lines, and equipment

- Boiler water originating from product steam boilers

- Water leaking from single-pass or closed-loop cooling systems

- Regeneration backwash waters from wastewater treatment plants

- Freezer meltwater and rainwater

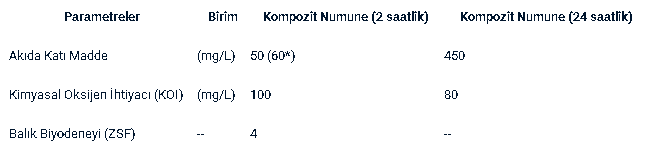

According to the first article of the Water Pollution and Control Regulation published in the official gazette on 31.12.2004,The purpose and scope of the regulation; The aim of this Regulation is to determine the legal and technical principles necessary to prevent water pollution in a manner consistent with sustainable development goals, in order to protect the potential of the country's underground and surface water resources and ensure their optimal use. This Regulation covers the quality classifications and usage purposes of water bodies, the planning principles and prohibitions regarding the protection of water quality, the principles of wastewater discharge and discharge permit principles, the principles related to wastewater infrastructure facilities, and the procedures and principles for monitoring and supervision to prevent water pollution. Our waters and used waters must be treated according to certain principles and criteria, and they fall into specific classes according to our regulation. The class of wastewater originating from the cocoa and chocolate, confectionery manufacturing industry, according to the regulation mentioned above, is provided in the table below.*If there is condensation water and dilution**What is Artemis Treatment Doing?**1. Reducing the volume of wastewater in the process by using measurement technology during the discharge of products from the lines,

2. Ensuring more efficient treatment by monitoring water consumption,

3. Since the collected wastewater must be neutralized before being discharged into the sewer, ensuring neutralization,

4. In accordance with legal regulations; pH, temperature, and wastewater volume are continuously monitored and recorded.Healthier and cleaner waters are an investment in our future. Invest in the future with us.

.jpg)