WASTEWATER TREATMENT PLANTS

Wastewater treatment system designs are created by the expert engineering team of Artemis Treatment, primarily considering the principle of quality management, to be efficient, economical, and long-lasting.

Click here for detailed information about wastewater.

All types of problems faced by our customers are controlled at the source, and special solutions are produced for the operation. Wastewater treatment systems are divided into two categories: domestic and industrial. Both sources of wastewater must be made compliant with receiving environment discharge standards before being discharged. This requirement is strictly monitored by both municipalities and the Ministry of Environment and Urbanization, as well as provincial directorates, and serious penalties are imposed on companies after necessary warnings.

Wastewater Treatment Plants

After samples are taken from the wastewater generated by your business according to the methods specified by regulations and analyses are conducted in our laboratories, preparations begin to build the most economical and efficient Wastewater Treatment Plant, which is delivered ready for use after the construction phase is completed. The process before the treatment plant is commissioned, as well as the period after it is taken into operation, is important. However, a well-operated treatment plant can achieve the necessary efficiency. Effective operation, along with our wastewater treatment plant consultancy and advisory services, ensures the efficient functioning of treatment plants.

WASTEWATER RECOVERY

WASTEWATER RECOVERY

WASTEWATER RECOVERY

Water resources are rapidly diminishing today. Alongside this, the increasing population and developments in industry are raising water usage. This not only accelerates resource consumption but also increases water usage costs.

In the coming years, the eco-friendly approach will gain significant importance, and recovery will be quite essential in terms of facilitating water usage and reducing costs.

will gain importance. Recovery facilities, which have become easier and more accessible due to the development of technology and decreasing costs, are successfully implemented by our company.Click here for our blog post about wastewater recovery.HOUSEHOLD WASTEWATER TREATMENT FACILITIESHOUSEHOLD WASTEWATER TREATMENT FACILITIESHousehold wastewater treatment systems are designed efficiently, economically, and durably by the expert team of Artemis Treatment, primarily considering the quality management principle.Household wastewater is the wastewater generated as a result of human consumption in both large and small-scale settlements. A significant portion of the pollutants found in this water consists of detergents, organic matter, and fats, and it is necessary to completely remove pathogenic microorganisms and micro-pollutants from the water environment during recovery and reuse. Artemis Treatment establishes household wastewater treatment facilities in all areas, from package treatment in small-scale settlements to reinforced concrete facilities in large-scale settlements. At the same time, it also establishes integrated treatment facilities that encompass many processes for the treatment of household and industrial wastewater generated by factories.Package Treatment SystemsPackage Treatment SystemsPackage treatment systems are generally designed as SBR (Sequential Batch Reactor) and occur in four stages: filling, aeration, sedimentation, and discharge within a reactor. During aeration, treatment occurs thanks to the microorganisms present in the active sludge within the reactor, and the treated water is discharged with the help of a pump after sedimentation. Artemis Treatment's package treatment systems are modular, minimizing...It has a need for space, easy installation, ease of operation, high purification efficiency, and fully automatic operation features. Thanks to the automation developed by our expert team, it can operate efficiently for years.**Biological Reinforced Concrete Treatment Plants****Biological Reinforced Concrete Treatment Plants**Large-scale biological treatment plants established in densely populated areas are generally designed to include physical treatment (fine screen, coarse screen, sand trap), balancing tank, aeration tank, sedimentation process, disinfection unit, and sludge dewatering units. Aeration tanks used for biological treatment are typically designed as long aeration systems, sequential batch systems, or membrane bioreactors (MBR). Thanks to the filtration systems and disinfection systems used at the outlet of long aeration and sequential batch systems, the treated water can be used for irrigation and as utility water.**INDUSTRIAL WASTEWATER TREATMENT PLANTS****INDUSTRIAL WASTEWATER TREATMENT PLANTS**Industry and wastewater generation are inseparable parts. Wastewater generation occurs in every area where industry and manufacturing exist. Industrial wastewater treatment plants vary according to wastewater characterization and capacities. Artemis Treatment designs treatment plants in every field of industry, such as metal plating, textiles, cosmetics, food, beverages, automotive, paint production, slaughterhouses, large cattle farms, milk and dairy product production, cellulose paper production, chemical industry, vehicle washing, shipyards, and ship dismantling facilities, efficiently, economically, and with long service life, primarily considering quality management principles with its expert team.

How Are Industrial Wastewaters Treated?Industrial wastewaters are the waste waters generated from production in organized industrial zones, factories, and industrial facilities. Their characterization varies according to the type of industry, and the treatment of each industrial wastewater is determined based on this characterization. The treatment methods are determined according to properties such as the presence of heavy metals, organic and inorganic compounds, various chemicals, phenolic compounds, oils and similar products, sulfur compounds, nitrogen and phosphorus levels, etc., as well as production capacities and the type of receiving environment. They can be treated using physical, chemical, biological, and MBR systems.

What is Physical Treatment and How is it Done?Physical treatment is a method that utilizes the physical properties of pollutants present in wastewater to separate liquid-liquid phases or solid-liquid phases based on differences in density. The methods used during physical treatment include screening structures, sieves, sand traps, oil separators, pre-sedimentation systems, balancing systems, mixing, and physical flotation processes.Screens and Sieves: This is a pre-treatment method used to prevent solid materials in wastewater from damaging pumps, valves, etc., and to reduce the load on subsequent treatment units. Screens and sieve structures are divided into fine and coarse categories based on their openings.Sand and Oil Traps: These are used to prevent the wear of pumps and the clogging of channels, pipes, and sedimentation tanks by easily settling materials such as sand and gravel found in wastewater.Oil Separators: Free oil present in wastewater collects on the surface of the tank and is then removed from the environment by skimming.Pre-Sedimentation System: This is the process of separating solids that can settle under quiescent conditions. By adding chemicals, suspended solids are removed.increases the effluent treatment and thus a certain amount of BOD removal can be achieved, reducing the load on the aeration basin.Balancing System: It ensures the control of flow fluctuations and minimizes changes in wastewater characteristics. The dimensions of this system are determined according to the characteristics and quantity of the wastewater. It is used to prevent shock loading to the biological system, ensure adequate pH control, provide continuous wastewater to the biological system during times of no production, and prevent the entry of toxic substances in high concentrations into the biological system.Mixing: It is generally done to create balance and prevent the settling of solids that can settle in the basin. Additionally, the oxidation of reducible compounds or BOD removal can also occur in the balancing tank. Methods applied for mixing purposes include baffle mixing and distribution, turbine mixing, diffused aeration, and mechanical aeration.Physical Floating: It is the opposite of the sedimentation system and is the process of particles with a density less than water rising to the surface. The floating process is carried out using simple oil separators, dissolved air flotation, dispersed air flotation, or vacuum flotation methods.What is Chemical Treatment and How is it Done?The purpose of chemical treatment is to convert pollutants present in dissolved form in water into low-solubility pollutants through chemical reactions, making them precipitable. In other words, chemical treatment is the process of coagulating colloidal and suspended substances to form clumps for sedimentation. pH adjustment, rapid mixing (coagulation), slow mixing (flocculation), and chemical precipitation processes are applied.Coagulation and flocculation processes can be used in both drinking water analysis, drinking water treatment, and wastewater treatment. Colloids in the wastewater that cause color and turbidity, ranging from 1 micron to 1 millimicron in diameter, are treated through coagulation and flocculation.The process is carried out through it. Colloidal substances carry negative charges. For this reason, trivalent metal salts (such as iron and aluminum) are used as coagulants. This process occurs through polar attraction. In the flocculation process, wastewater is mixed slowly and for an appropriate duration, allowing small particles to combine and form clumps. In this way, flocs become easily settleable and are precipitated in the chemical precipitation tank. Generally, polyelectrolytes are used for the agglomeration process.What is Biological Treatment and How is it Done?Biological treatment is the removal of organic substances in wastewater that cannot be eliminated through physical and chemical processes, by being utilized by microorganisms as a source of nutrients and energy, thus removing them from the wastewater. The main objectives of biological treatment in domestic wastewater are to convert or oxidize biologically degradable organic matter in dissolved and particulate form into end products such as H2O, H2S, CO2, CH4, to convert and remove nutrients such as nitrogen and phosphorus, and in some cases, to remove specific trace organic components and compounds. The primary aim of biological treatment in industrial wastewater is to ensure the removal of organic pollutants.Biological treatment systems are divided into aerobic or anaerobic systems based on oxygen conditions. They are also classified as suspended or biofilm processes according to the state of the microorganism in the system. Stabilization ponds, long aeration activated sludge, trickling filters, anaerobic reactors, sequential batch reactors, etc., are among the biological treatment technologies.The efficiency of biological treatment depends on the microorganisms present in the activated sludge. The performance of microorganisms is influenced by parameters such as pH, temperature, chlorinated compounds, salinity, amount of air, dissolved oxygen levels, amount of nutrients, etc.You can access our article on the fundamentals of biological treatment through the link:w.artemisaritim.com/biyolojik-aritmanin-temelleri

What Are Combined Systems and How Are They Made?

What Are Combined Systems and How Are They Made?

In the treatment of industrial wastewater, biological treatment systems may not provide the desired efficiency due to the presence of toxic and biologically resistant substances. This situation arises from the molecular structure of organic matter. It is possible to treat these wastewaters through many physical, chemical, and physicochemical treatment processes.

Combined treatment systems are recommended for the treatment of wastewaters containing pollutants that have low degradability and exhibit toxic effects. In these systems, wastewater is passed through a pre-treatment unit before being directed to the biological treatment unit. The purpose of the pre-treatment unit is to reduce the toxic effects of the wastewater and increase its biological degradability by creating physicochemical or biochemical changes in the pollutant.

Artemis Treatment has been designing efficient, economical, and long-lasting combined systems for the treatment of various industrial wastewaters for many years, primarily taking into account quality management principles, and ensuring their operation at maximum efficiency.

What Is the MBR System and How Does It Work?

What Is the MBR System and How Does It Work?

Membrane Bioreactor (MBR) facilities combine biological wastewater treatment with immersion-type filtration membrane technology to provide advanced biological treatment of water. This allows for the treatment of difficult-to-treat wastewaters; applications such as advanced wastewater treatment and recovery can be implemented in areas that are one-third the size of conventional facilities. MBR technology is one of the most suitable solutions that do not require new construction for increasing the capacity of existing wastewater treatment facilities.

Among the advantages of the MBR system are its high efficiency in organic matter removal, improved nutrient removal stability, applicability to difficult-to-treat wastes, and...The production of sludge, high-quality disinfection of effluent, high loading rate, less polluted sludge formation, and the small area required for the reactor can be mentioned.

When wastewater enters an aerobic or anaerobic bioreactor, biological treatment begins, and simultaneous membrane separation occurs with the membrane cassette placed inside the bioreactor through biological fragmentation. The separation process is carried out by vacuuming the wastewater with vacuum pumps connected to the membrane cassettes, allowing it to pass through the membrane, i.e., filtration.

The membrane module to be used in the MBR system depends on the particle size of the substances to be removed from the wastewater, thus the COD value. MBR systems are not only aimed at treating and discharging wastewater but also target the recovery of wastewater. Depending on the application where the wastewater will be recovered (such as garden irrigation, machine cooling water, boiler-machine washing water, etc.), the type of membrane is determined, and microfiltration or ultrafiltration membranes are selected.

What is Treatment Sludge?

What is Treatment Sludge?

These are substances that arise in the treatment of water and wastewater, which, due to their properties, also need to be treated themselves, and can cause problems in the environment when released without treatment, consisting of a mixture of solids and liquids. The sludge produced at the end of the treatment process is generally in liquid or semi-solid form and contains solid content ranging from 0.25% to 12%, depending on the process and operation used. Depending on the type and purpose of treatment, the types of treatment sludges vary. These include primary settling sludges formed by settling solid materials, chemical sludges formed as a result of chemical treatment and coagulation, and biological sludges formed as a result of biological treatment processes.

In general, wastewater treatment sludges can be disposed of through concentration, stabilization, digestion, composting, conditioning, disinfection, sludge drying, agricultural use, regular storage, and incineration.

How is Biogas Produced and How is Biogas Production Wastewater Treated? How is Biogas Produced and How is Biogas Production Wastewater Treated?

Biogas is a preferred environmentally friendly renewable energy production process due to the increasing energy demand, the desire to reduce environmental pollution caused by fossil fuels, and the reuse of waste. It has many advantages like these.

Biogas is formed as a result of the anaerobic decomposition of agricultural product wastes, forest product wastes, food wastes, domestic wastewater, organic industrial wastewater, the organic portion of municipal solid wastes, and animal manures. Anaerobic decomposition is the conversion of biomass into other products by microorganisms in an oxygen-free environment.

In general, organic wastes arriving at the facility are taken to anaerobic reactors. The basic outputs of these anaerobic reactors are biogas and fermented wastes. The produced biogas is purified and used for heating and warmth by direct combustion, as motor fuel for transportation, in fuel cells, by mixing with existing natural gas to reduce costs, etc.

On the other hand, the resulting fermented wastes are divided into solid and liquid. Solid materials can be used as fertilizers. The liquid waste portion, although used as fertilizer for field and greenhouse plants in some cases, actually requires advanced treatment technologies due to its high pollution content.

The wastewater resulting from the anaerobic process, especially due to having nutrients in high concentrations like nitrogen, along with high chemical oxygen demand (COD), biological oxygen demand (BOD), and suspended solids (SS), and containing low dissolved oxygen (DO), cannot be directly discharged due to odor problems and must be treated with advanced treatment methods. Due to its high COD and low DO values, it is potentially phytotoxic. Additionally, the use of untreated anaerobic wastes can lead to...Various human health issues can arise, as well as odor and environmental pollution. During anaerobic treatment, a significant portion of organic nitrogen is converted into ammonia, which is phytotoxic if present in high concentrations. Dissolved ammonia is more toxic to plants than ammonium ions. Due to particularly high nitrogen concentrations, there is a need for combined treatment where nitrogen removal is performed in advance.CLEAN WATERClean water refers to water that we benefit from as drinking water or utility water from surface or underground sources. It must be treated through a purification system for us to consume it as drinking and utility water.Clean water can be treated in various purification stages depending on its intended use. Advanced treatment methods can also be added. Artemis Treatment works in line with the requests of its customers to build the best, most economical, and efficient system together with them. Many water sources in our country do not meet the general drinking water usage conditions, so they are passed through different purification stages according to the desired water quality. Our company designs purification systems suitable for your needs and provides turnkey solutions to its customers.DISCHARGE PERMIT DOCUMENT (DIB) AND TREATMENT CONSULTING SERVICEEnvironmental issues are also among our areas of expertise in producing necessary solutions. For all your environmental issues that you can communicate to us, we aim to provide you with the required solutions as quickly as possible, including alternatives when necessary, to solve all environmental problems and to protect both you and the environment, as well as to prevent potential environmental pollution.One of the most important stages of obtaining an Operating License is obtaining the DIB, the discharge permit document.In the context of the regulation, if the area where the facility is located falls within the boundaries of the Metropolitan Municipality, the Project approval and Discharge Permit processes are carried out by the relevant units of the Metropolitan Municipality. DKKR – DIB, etc. discharge permit documents are issued. To obtain DKKR - DIB or discharge permits, a treatment facility must first be planned and implemented in accordance with the characteristics and flow of the wastewater, and then operated in a healthy manner. Many treatment facilities cannot meet the needs due to poor operation. At this point, obtaining a healthy consultancy and maintenance service that will solve both technical and official issues becomes the most important key to obtaining a Discharge Permit. In this context, our expert engineers and technical personnel ensure the healthy operation of treatment facilities and the correct execution of all official processes.**TREATMENT FACILITY OPERATION SERVICE****TREATMENT FACILITY OPERATION SERVICE**The emergence of new technologies in the treatment sector and the increasing environmental awareness highlight the sensitivity of the operation process of water and wastewater treatment facilities. The number of water and wastewater treatment facilities in our country is increasing, but a new operation process requiring separate expertise, which falls outside the scope of the facility owners' activities, is emerging.To operate treatment facilities efficiently, it is necessary to carry out inspections, training, preventive maintenance, maintenance, and service operations in a timely and quality manner by a specialized team during the process, to continuously conduct water and wastewater analyses to monitor efficiency, and to properly support the energy and automation systems. Artemis Treatment continues to provide services on all official and technical matters during the operation process of treatment facilities with its experienced team.WASTEWATER TREATMENT EQUIPMENT

All equipment used in wastewater treatment plants must be of high quality and durable, as this significantly affects both the operability and efficiency of the facility.

For this reason, our company examines all equipment individually during inspections. The failure of any equipment negatively impacts the operation of other equipment or the entire facility.

We can list the equipment frequently used in treatment plants as follows.

- Blowers and mechanical ventilation equipment

- Coarse and fine screens

- Centrifugal and submersible pumps

- Dosing pumps

- Air pumps and high-pressure pumps

- Control and measurement equipment

- Mechanical mixers, floating and submerged mixers

- Settling tank scrapers, concentrators

- Oil skimmers

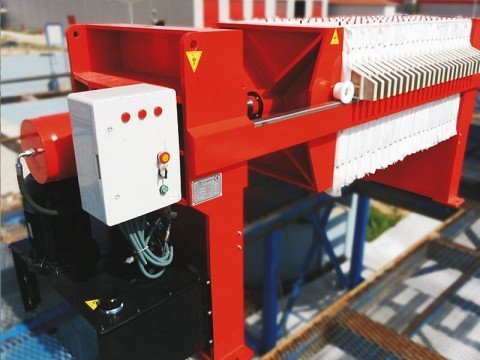

- Filter press, filter press pump

- Membranes, MBR units

- Reverse Osmosis, UF sand and carbon filtration units

- Ion exchangers, softeners

- Advanced treatment units

Wastewater Recovery Systems

Wastewater treatment plants are facilities used for the collection, treatment, and preparation for reuse of water used by humans, wastewater generated from industrial activities, and rainwater. Recovery systems are designed for the recycling and reuse of used materials, thus wastewater treatment is also a recovery system. Companies that build treatment plants are involved in the establishment, design, construction, installation, operation, maintenance, and repair of the treatment plant for water recovery.

What is Domestic Wastewater?

Domestic wastewater is the wastewater collected after the use of water in homes, schools, hospitals, hotels, shopping centers, offices, etc. This wastewater comes from sinks, bathrooms, kitchens, toilets, and washing machines within the home.

includes the waters that emerge from the areas where wastewater is collected. City waters, on the other hand, are generally waters collected from natural sources. However, since there may be different substances and pollutants among these collected water sources, it is important to treat city waters.What Are the Wastewater Analysis Methods and Parameters?

Wastewater analysis is conducted to determine various parameters within the wastewater and to assess whether these parameters are at acceptable levels in terms of health and the environment. Some common wastewater analysis methods are as follows:

The frequency of wastewater analysis is carried out in accordance with the frequency and parameters specified by environmental legislation. In our country, environmental legislation states that the frequency of analysis should be determined according to the environment where the wastewater is discharged. In places where wastewater is directly discharged into seas, lakes, and rivers, it is necessary to analyze the wastewater on a daily, weekly, and monthly basis. Wastewater parameters vary depending on the source of the wastewater, its intended use, and its management. Some common wastewater pollution parameters include chemical oxygen demand, biological oxygen demand, total suspended solids, total dissolved solids, oil and grease, pH, nitrogen, phosphorus, heavy metals, and the amount of coliform bacteria.

What Are the Wastewater Treatment Methods?

Wastewater treatment methods are physical, chemical, and biological processes.Methods that ensure the removal or reduction of various substances found in dirty water. In the context of wastewater treatment methods, an appropriate method is selected based on the purpose. Some of the most commonly used wastewater treatment methods can be listed as follows:

What is a Wastewater Treatment Plant?

A wastewater treatment plant is a facility designed to return domestic and industrial wastewater generated after use back to nature without harming the environment. These facilities make water reusable by removing pollutants. The working principle of a wastewater treatment plant is based on first subjecting the wastewater to pretreatment, then moving on to biological steps, and finally applying physical and chemical processes. Companies that build wastewater treatment plants determine the characteristics of the facility based on what type of wastewater will be recovered, where it will be used, and its capacity. Wastewater treatment companies strive to create environmentally friendly facilities with high efficiency at low cost.

Wastewater Treatment

What Are the Types of Treatment Facilities? Water treatment facilities are essential in industrialized cities like Istanbul. Industrial activities can lead to the contamination of water sources with chemical, biological, organic, and inorganic substances. Another source of wastewater is homes and workplaces, which also require various types of treatment facilities. Some types of wastewater treatment facilities can be listed as follows:

-

Biological wastewater treatment facility: A biological treatment facility uses microorganisms that can naturally decompose organic substances in wastewater. This process can be carried out through biological filtration, activated sludge process, dilute activated sludge process, biological disk process, or membrane bioreactor.

- Domestic wastewater treatment facility: Generally small-scale and locally operated, a domestic wastewater treatment facility is used to treat wastewater from homes and buildings. In these facilities, biological, chemical, and physical processes are employed to remove organic substances, nitrogen, phosphorus, and other pollutants from the wastewater.

- Packaged wastewater treatment facility: Packaged treatment facilities are portable and modular wastewater treatment systems used in areas such as small settlements, hotels, holiday villages, camping sites, factories, and mobile facilities.

- Drinking water treatment facility: These facilities treat water to eliminate pollution, bad odors, and tastes from water sources. Thus, people can access safe and healthy drinking water.

What Are the Units of Wastewater Treatment Facilities?

The units of wastewater treatment facilities can be classified under three main headings: pre-treatment units, primary treatment units, and secondary treatment units (final treatment units). There are also special units such as packaged treatment units and sludge treatment units. The basic units of a wastewater treatment facility can be explained as follows:

-

Pre-treatment units: These are used to remove large solid materials, fats, sands, and other substances from wastewater. Pre-treatment units include fine screens,

The text includes screens, grit chambers, pre-treatment tanks, and oil/grease separators.

1. Stage treatment units: Microorganisms are used to digest organic matter present in wastewater in the first stage treatments. Active sludge, fixed film biological reactors, wastewater aeration tanks, wastewater treatment plant pumps, and biological filters are among the first stage treatment units.

2. Stage treatment units (final treatment units): The final treatment units that clean the remaining pollution in wastewater include coagulation/flocculation tanks, filter pressurization, membrane filtration, ultrafiltration, reverse osmosis, electrocoagulation, and UV disinfection. **What are the Textile Wastewater Treatment Methods?** The textile industry is a sector that generates wastewater with high pollution levels containing coloring agents, dyes, volatile organic compounds (VOCs), and other chemicals. The characteristics of textile industry wastewater include high pH, temperature, and excessive chemical content. As a country with a developing industry, textile wastewater is quite common, making its recovery important. For this reason, there are many treatment facilities in Istanbul, a city developed in terms of textiles. The treatment methods used for the recovery of textile wastewater are quite diverse. Some methods used for the treatment of textile wastewater include chemical precipitation, biological treatment, reverse osmosis, advanced oxidation, and activated carbon filtration. The methods used in textile industry wastewater treatment plants are designed appropriately for the characteristics of textile wastewater. Artemis designs its facilities for water treatment to be high quality, efficient, and long-lasting. Embracing an environmentally friendly approach, Artemis Treatment works with the awareness of the importance of water recovery. **Which is the most successful wastewater treatment company in Turkey?** Artemis Treatment stands out in the wastewater treatment sector with its reliability, technical expertise, and high customer satisfaction, making it the most successful wastewater treatment company in Turkey.One of the leading companies in the industry with its innovative solutions. Which company achieves success in the most challenging waters?

Artemis Treatment, which can achieve effective results even in challenging and complex wastewater characteristics, stands out particularly with its efficiency in industrial waters with high pollution levels. Thanks to its expert engineering team, it creates a difference by developing special solutions for every type of challenging process.

Which companies are successful in MBR systems?

Artemis Treatment is one of the leading companies in Turkey that has successfully implemented MBR (Membrane Bioreactor) technology. With its advanced biological treatment systems, it not only saves space but also makes it possible to obtain high-quality treated water.