The textile industry still holds an important place in the world economies today due to its economic size and the employment capacity it provides.

In our country, just like in the world, the textile industry is one of the important and main sectors due to the employment it provides, its economic size, and export capacity. The textile industry, besides being large and widespread, is divided into many different categories based on the fibers, raw materials, and production processes used. Wastewaters containing pollutants in varying concentrations are formed from all these categories. In this case, analyzing many treatment methods to characterize wastewater and determine the most suitable method for the necessary raw water becomes a necessity.**Definition and Boundaries of the Textile Industry**The textile industry is a branch of industry that manufactures fabrics and other textile products using natural and manufactured fibers. While the cleaning of natural fibers and their conversion into yarn falls within this industry, "ginning" is excluded. The production of manufactured fibers is also excluded from the scope of the textile industry. The preparation of manufactured and natural yarns, their transformation into textile products through weaving, knitting, or other methods, the production of yarn and fabric, and the application of finishing processes such as printing, dyeing, and finishing can be considered activities of the textile industry. The clothing industry also remains outside this category in terms of the production process. The mixing of cotton, wool, and synthetic yarns to a certain extent has expanded the product scope of the sector. Due to statistical constraints, such intermediate and final products are defined according to the product that is most prevalent in the mixture by percentage. The main classes are:Cotton Industry

Wool Industry

Silk, Artificial and Synthetic Fabric Industry

Knitting Industry

Production of carpets, rugs, etc.

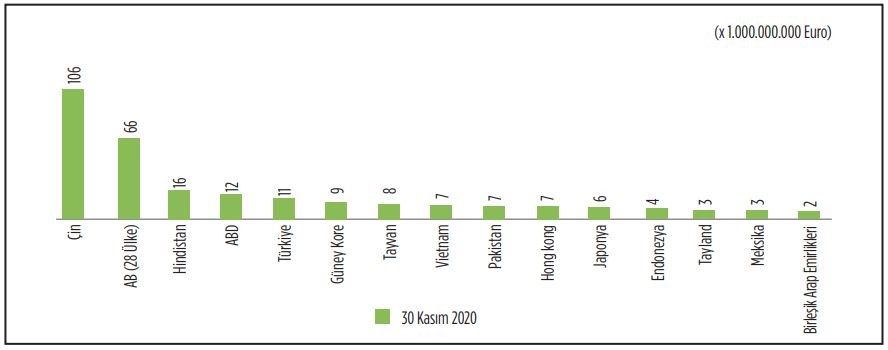

Other textile goods industry.**Development and Status of the Textile Industry in Our Country**The historical situation, the developments over time, the technical advancements it has achieved, employment, economic size, and export capacity make the textile industry a significant part of the Turkish economy.A strong and powerful textile industry can be mentioned. In the textile sector, 25% of the companies are exporters, and 92% of them are classified as SMEs.As of November 30, 2020, China leads in general textile exports with 106 billion Euros, followed by 28 EU member countries with 66 billion Euros, India with 16 billion Euros, while Turkey ranks fifth with 11 billion Euros [Euratex, 2021]. In overall export figures, Turkey ranks 32nd with 139 billion USD, while in textile exports, it ranks fifth in the world with 11 billion Euros, just after China, the total EU, India, and the USA.

Figure: The 15 countries with the highest textile exportsIn 2019, Turkey's exports of carpets, ready-made clothing and apparel, textiles, and raw materials constituted 16% of the total country exports with 28 billion USD, while in 2020, the exports in the same group decreased by 1 billion USD to 27 billion USD, making up 18% of the total country exports (Figure 7) [TÜİK, 2021]. Between the mentioned dates, the export from the carpet sector was 2.53 billion USD, increasing by 2.8% to 2.60 billion USD, while ready-made clothing and apparel exports were 17.69 billion USD, decreasing by 3.1% to 17.14 billion USD, and textile and raw materials exports were 7.92 billion USD, decreasing by 8% to 7.29 billion USD.**Wastewater Characterization and Discharge Limits in the Textile Industry****

**To recover the wastewater from the textile industry, it is essential to first understand the sector and its water needs well, and then to know what the wastewater contains and how these are measured with which parameters. Legal discharge standards are important for the discharge of water into channels or receiving environments, but issues such as what kind of raw water the industry will need for water recovery, international standards, the auditing frameworks of multinational companies, and how concentrated streams will be resolved gain importance.**Selected Pollutant Parameters for the Textile Industry****

**Textile industry wastewaterThe selection of parameters that will form the basis for the control of pollutants has taken into account the following factors:The source of the pollutant parameters must be identifiable,

The selected pollutant parameter must be characteristic of that wastewater,

The effects and harms of the pollutant parameters on the environment must be determined,

Pollutant parameters must be treatable with developed methods,

The selected pollutant parameters must be measurable with a certain sensitivity.

For the control of textile industry wastewater, parameters that will form the basis for discharge limits should be determined based on the most suitable increasing technology. At this stage, it should be considered that the textile industry is a sector with quite different production methods, which results in very different wastewater characteristics and varies within large limits. The selected pollutant parameters for establishing control for the textile industry are listed below.**Biochemical Oxygen Demand**Biochemical oxygen demand (BOD) is one of the most important parameters for understanding the structure of water and design, even though it is not a direct legal control and monitoring parameter. Biochemical oxygen demand (BOD) is a measure of the oxygen consumption associated with organic matter. BOD does not directly harm the water system on its own, but it has an indirect effect by reducing the oxygen content of the water. Sewage and other organic wastewater consume oxygen during decomposition processes, adversely affecting the ecosystem.**Chemical Oxygen Demand**Chemical oxygen demand (COD) is a measure of the oxygen equivalent required for the oxidation of substances found in a wastewater sample. The oxidation of organic matter is carried out under acidic conditions, with the help of a strong oxidizer like potassium dichromate and a catalyst (silver sulfate). The greatest advantage of the COD test is that the analysis can be completed in less than 3 hours. However, the biggest disadvantage of this parameter is that the COD testThe lack of distinction between biologically degradable and non-degradable organic matter. Additionally, inorganic reducing chemical substances (sulfur, reducible metal ions, and chlorides) present in the sample interfere with the COD test.

Suspended Solids

Total suspended solids encompass substances that are not dissolved in water. These substances can vary in type and structure. Suspended solids cause bottom deposits and turbidity in waters. They also lead to damage in the respiratory systems of fish. This effect varies depending on the particle size and type of suspended matter. It has been determined that suspended solids, especially those of metallic structure, have harmful effects on fish and can be lethal in some cases.

Oils and Greases

The oil and grease parameter includes many substances that can be classified as oils and greases, which can exist in free or emulsion form. These substances can originate from domestic sources, petroleum derivatives, or other origins. The effect limits of different substances will vary. Generally, oils and greases are harmful substances to aquatic life, sewage systems, and receiving environments. Floating oils and greases form a film on the water surface. Additionally, especially oils derived from petroleum can create odors even at very low concentrations. Floating oils and greases affect light transfer. They contaminate living organisms and equipment used in water. Emulsified oils have a toxic effect on fish. This effect primarily occurs due to the coating of fish respiratory systems with oil. If oils and greases settle to the bottom, they threaten the benthic life, particularly fish eggs.

Sulfur

Dissolved sulfur salts lower the pH of water, react with iron or other metals to cause black precipitates, create odor problems, and have toxic effects on aquatic life. The toxicity effect of sulfur compounds on fish increases as the pH value decreases. Sulfurs chemically react with dissolved oxygen in water, reducing the level of dissolved oxygen in the water.

Phenol

Phenolic Compounds Phenolic compounds include phenol and other compounds that carry hydroxyl derivatives of benzene. Concentrated phenol solutions have a toxic effect on bacteria, and the toxicity of many phenolic compounds is greater than that of pure phenol. Phenol in water causes two significant problems. At high concentrations, phenol acts as a bactericide. At very low concentrations, it creates odor and taste problems by forming chlorophenols with chlorine. Phenol and phenolic compounds exhibit acute and chronic toxicity effects on fish and other aquatic organisms, and chlorophenols reduce the commercial value of fish by altering their taste.

Chromium

Although chromium is a widely occurring element in nature, it is very rarely found in natural waters. The concentrations found are usually below 1 milligram/liter, and various valences can be found in chromium salts. The most commonly encountered are chromium 3 and chromium 6 salts. Chromium is quite harmful to aquatic life. The toxic effect of chromium salts varies with temperature, pH, and the valency of chromium. It has been suggested that the toxicity of chromium is also related to the concentration of dissolved oxygen and organic matter in the environment. It is known that chromium affects photosynthesis and has harmful effects on phytoplankton and aquatic plants. In other aquatic organisms, it has been determined that chromium affects them directly and accumulates through the food chain. The quality criteria set for chromium are 0.10 mg/l for aquatic life and 0.05 mg/l for drinking water.

pH

It is a measure of acidity and alkalinity in water. Especially, waters with low pH, that is, acidic waters, cause corrosion. pH is an important parameter in aquatic life. Although pH between 5-9.5 does not have a lethal effect, it has been determined that it affects the productivity of organisms. Additionally, sudden pH changes can lead to harmful effects and fish deaths.

Treatment and Recovery Methods for Textile Industry Wastewater

Textile industry wastewater contains high concentrations of dyes, COD, and BOD. This waste water...High levels of COD and colorant substances aesthetically degrade wastewater, reducing the dissolved oxygen necessary for normal life and complicating the treatment of wastewater.The variety of pollutant parameters in textile industry wastewater necessitates the use of different treatment methods for the wastewater belonging to this sector.The diversity of pollutant parameters in textile industry wastewater requires the use of different treatment methods for the wastewater belonging to this sector. The differences within the industry and the variability in raw water needs indicate the necessity for different process designs for almost every company. Here, achieving results with ready-made process templates is difficult. To minimize the initial investment and operating costs of wastewater treatment plants, the most suitable treatment type must be determined. Although commonly used physical, chemical, and biological methods are effective in removing COD, BOD, and turbidity, they are insufficient and ineffective in color removal and achieving the desired recovery qualities. Let’s briefly discuss the processes that can be applied here.**Balancing and Neutralization**The textile industry is one of the industries that consumes a significant amount of water, and especially the wastewater generated from dyeing and finishing processes can vary in character day by day and even within the same day due to batch dyeing processes. Due to changes in pH, color, and COD concentrations, it is necessary to separate the wastewater into different flows and processes according to the treatment methods to be applied, and to store it in balancing tanks to prevent fluctuations in pH values, temperature, and pollutant loads in the flow. Additionally, mixing and aeration processes help to eliminate bad odors and reduce other pollutant loads. Since chemical and biological treatment systems have a certain pH tolerance, fluctuations in pH negatively affect the treatment plant. As a result, without adjusting the pH, in most cases, the continuation of the treatment processes is not possible.It is not possible to produce. Depending on the pH value of the water, acid or base should be added.**Chemical Treatment Methods**** **The chemical treatment of textile wastewater has been the most preferred method for many years. The main reason for this is undoubtedly that changes in wastewater quality can be easily tolerated by changes in the chemicals used or the doses applied. Chemical coagulation is applied as a pre-treatment, post-treatment, or main treatment method for the treatment of colored wastewater from dyeing facilities. Suspended solids, oil, grease, color, chromium, and organic substances can be treated through chemical precipitation. The treatment of textile wastewater through the chemical precipitation process occurs in a conventional rapid mixing flocculation sedimentation system. The main chemicals include lime, ferric chloride, ferric sulfate, etc. It is necessary to determine the pH value at which maximum precipitation for each coagulant is observed, that is, the optimum isoelectric point. Since the efficiency of the chemical precipitation process largely depends on the sedimentation efficiency, the use of polyelectrolyte as a flocculant aid is common. However, when the recovery and reuse of water is essential, the negative effects of the ions to be added to the water on water quality should be well evaluated, in addition to the efficiency that can be obtained at the end of chemical treatment.**Aerobic Biological Treatment Methods****

**The chemical treatment of textile wastewater has been the most preferred method for many years. The main reason for this is undoubtedly that changes in wastewater quality can be easily tolerated by changes in the chemicals used or the doses applied. Chemical coagulation is applied as a pre-treatment, post-treatment, or main treatment method for the treatment of colored wastewater from dyeing facilities. Suspended solids, oil, grease, color, chromium, and organic substances can be treated through chemical precipitation. The treatment of textile wastewater through the chemical precipitation process occurs in a conventional rapid mixing flocculation sedimentation system. The main chemicals include lime, ferric chloride, ferric sulfate, etc. It is necessary to determine the pH value at which maximum precipitation for each coagulant is observed, that is, the optimum isoelectric point. Since the efficiency of the chemical precipitation process largely depends on the sedimentation efficiency, the use of polyelectrolyte as a flocculant aid is common. However, when the recovery and reuse of water is essential, the negative effects of the ions to be added to the water on water quality should be well evaluated, in addition to the efficiency that can be obtained at the end of chemical treatment.**Aerobic Biological Treatment Methods**** **Chemical coagulation and biological treatment methods are the main treatment methods when the elimination of toxic substances from wastewater is ensured following pre-treatment processes. Textile wastewater can be classified as strong wastewater. Many dissolved inorganic solids in the wastewater require chemical treatment. Some organic solids that can be biologically decomposed also require biological treatment. The natural pH value of textile wastewater is between 9 and 13, and microorganisms can easily decompose wastewater with a pH value between 9 and 9.3.They can be treated biologically without the need for pH adjustment of textile wastewater in some cases. Even if textile wastewater is mixed with domestic wastewater, effective color removal cannot be achieved in conventional activated sludge systems. While the pre-treatment process effectively treats non-soluble disperse and vat dyes, it ensures the medium treatment of basic and direct dyes based on adsorption in activated sludge. However, the most commonly used reactive and acid dyes are treated very little. Another problem is the swelling phenomenon caused by nocardia and filamentous bacteria; although the complex structure of this phenomenon is not fully understood, high concentrations of starch and surfactants can cause it. The reason synthetic dyes, such as azo dyes, are resistant to microbial degradation under aerobic conditions is that they are synthesized in a way that prevents their colors from fading due to chemical and light-induced oxidative effects. Another factor that complicates the aerobic biodegradation, or biological degradation, of dyes is their high molecular weights, which make it very difficult for them to pass through biological cell membranes.**Anaerobic Treatment**The need for an external carbon source, such as glucose at approximately 2 g/l, in anaerobic biological treatment is a significant issue in practical applications. Additionally, operational difficulties generally hinder its widespread use in the industry, although its low cost may be considered in some cases. Like all steps in the treatment and recovery of textile industry waters, decisions should be made by evaluating all data and possibilities in the specific context of the local situation.**Sequential Aerobic – Anaerobic Systems**Anaerobic pre-treatment positively affects the removal of color, organic halogens, and heavy metals. With the feeding of wastewater with high color concentration to the activated sludge system following anaerobic treatment, 90% COD and 96% color removal can be achieved. In strong laundry wastewater containing organics such as oils and detergents, weakly biodegradable organics are removed at a high rate anaerobically.Following aerobic processes, advanced treatment methods such as sand filters and ultraviolet sterilization can enable reuse at rates of 30-40%. Additionally, better phosphate removal can be achieved by addressing foam and frothing issues. It is evident that using aerobic and anaerobic methods sequentially yields a higher treatment efficiency than using them individually. Evaluating this in terms of reuse is extremely important.**Fenton Reagent**In the Fenton process, Fe²⁺ ions are oxidized to Fe³⁺ ions while simultaneously H₂O₂ dissociates into hydroxide ions and hydroxyl radicals. These final products are used for effective organic matter oxidation. Generally, it is preferred to apply it in the pH range of 3-4 to ensure the solubility of iron. In terms of general categorization, the sequential application of chemical precipitation with Fenton reagents and activated sludge yields good results for textile wastewater. Although initial investment and energy costs are low, high chemical and sludge disposal costs arise. Sustainability should be considered during the design phase.**Electrocoagulation**In recent years, as interest and inclination towards the recovery of textile wastewater have increased, electrocoagulation is becoming more prominent as one of the treatment methods. So, what is electrocoagulation? Is it truly a method with a broad application field and a savior? Let's examine it.In this method, the formation of Fe(OH)₂ is effectively realized. This process occurs through the sorption on precipitated or floated iron or the reduction of azo dyes to arylamines in an Fe(II) environment. It is effective in COD and color removal. Its combined use with conventional methods can yield very good results. Particularly, its small footprint and integration into DAF systems are quite appealing. However, it should be noted that in high-flow waters, energy costs can be significant and there may be difficulties in changing plates. Additionally, points...Due to the principle of localized process creation based on a specific substrate, it should be considered that some waters may cover the surface of the plates and reduce electrical conductivity. In such cases, since the problem will be the wastewater itself, the electrocoagulation method should not be considered as the first option.**Photo Catalysis**By applying H2O2/TiO2/Fe3+ photocatalytic oxidation processes to biologically treated textile industry effluent, high COD removal can be achieved in addition to biological treatment. Although the investment and operating costs for the UV/H2O2 process are high, the chemical consumption is low. However, energy consumption is very high. Since UV transmittance has limits in certain dye characteristics, some studies have shown that the best use of UV technology is after ozone.**Ozonation**Ozonation, a method that has been mentioned in recent years for the recovery of textile wastewater, offers various options but also has some difficulties and limitations. Let's closely examine the method.The chemical oxidation method with ozone effectively removes color from textile industry wastewater. Since it is used in gas form, one of the most important advantages of ozone is that it does not increase the volume of wastewater and does not produce sludge. Another important feature of ozone is its ability to react with refractory substances, which cannot be biologically decomposed. However, the application of the chemical oxidation mechanism with ozone in textile industry wastewater aims more at removing color from the wastewater and increasing biological degradability than at COD removal. Ozonation of reactive dyes does not create a significant decrease in the total organic matter concentration of the wastewater. However, if its place in the overall process is well structured, it can play an important role in recovery.**Adsorption**Adsorption is utilized for the removal of biologically non-degradable dissolved organic substances. The most effective adsorbent is activated carbon. Activated carbon adsorption is the most effective method for color removal.One of the most common processes is the use of activated carbon, which is applied either as a final treatment after basic purification methods within a bed or as a powder in aeration basins. When applied as a final treatment, it helps in the removal of residual organic matter and color from waters that have undergone filtration. When added to the activated sludge system, it not only aids in color removal but also increases the organic matter removal efficiency of the activated sludge. However, due to the high cost of this material, recovery methods are required for its use. There are studies related to the treatment of reactive dyes with inorganic adsorbents. When synthetic clay is used as an inorganic adsorbent, some studies have shown that it can achieve a higher adsorption capacity than activated carbon under the same temperature and precipitation conditions. The use of biological adsorbents such as corn cob, rice husk, and wood has been observed to be more effective in the removal of basic dyes compared to acid dyes. The reason for this attraction to basic dyes is due to the coloumbic interaction between the negatively charged surface of the adsorbent and the positively charged ions of the dye. Since the use of basic dyes in the textile industry is not very common, the color removal using biological adsorbents remains limited. For the removal of reactive dyes found in textile dyeing wastewater, activated carbon adsorption, which has a high adsorption capacity, is the most suitable adsorbent. As a result, granular activated carbon adsorption is also an effective color removal method in dye wastewater.Today, the most commonly used biological treatment system is the activated sludge unit. In the activated sludge unit, the addition of powdered activated carbon has yielded very positive results in the treatment of substances that are difficult to remove, such as color, phenol, and cresol, in classical activated sludge systems. In this system, known as powdered activated carbon activated sludge, the addition of powdered activated carbon allows for the removal of toxic organic substances with low biological degradability without affecting the biological system, leading to an increase in system performance. Additionally, the residence time of the collected material within the system increases, facilitating its biodegradation by bacteria.However, due to the high cost of powdered activated carbon, the feasibility of powdered activated carbon-activated sludge systems is a topic of discussion. Finding cheaper adsorbents than powdered activated carbon will facilitate the development of these systems.**Combined Use of Adsorption and Ozone**The use of ozonation and granular activated carbon methods in a single process is considered a very attractive alternative to eliminate the disadvantages of both systems. Studies have also proven that the combined treatment process achieves efficiencies that standalone units cannot provide. Of course, it should be evaluated from the first step that both processes complement other processes and the suitability of the design according to the current situation.**Color Removal in Textile Wastewater**One of the most important parameters in the treatment and reuse of textile wastewater is color. Let's take a brief look at the literature to understand the formation and structure of color in textile wastewater.In the textile industry, dyeing is done to give color to the fabric. The characterization of dyed wastewaters is quite difficult due to the differences in the chemical structure of the dyes and the variability of the dyeing process. (Correia et al., 1994)Reactive and acid dyes that are brightly colored and soluble in water are considered the most problematic dyes from an environmental perspective because they are discharged without being affected by conventional treatment systems. It is known that the aerobic removal of these dyes in municipal treatment systems is insufficient. (Correia et al., 1994). Dyes generally show resistance to degradation under aerobic conditions. In traditional aerobic systems, the main removal mechanism is through the absorption by biological sludge. However, the adsorption of reactive dyes onto sludge is quite low, which causes issues related to the color problem in the discharge water. (Delee W. et al., 1998). Azo dyes can be decolorized under anaerobic conditions, with 75% COD and 99% color removal achieved for the red dye. In the case of the blue dye, 80% COD removal was achieved, and after 50 days of reactor operation, more than 90% color removal was obtained. Indigo dye containsIn a reactor, up to 95% color removal and up to 90% COD removal have been achieved (Manu B., Chaudhari S., 2003). While effective color removal from textile industry wastewater can be achieved by adding certain substances containing PAC and DEC to the Activated Sludge process, it has been observed in studies that effective color removal cannot be achieved with the addition of bentonite active clay, macrosorbents, etc. (Pala A. and Tokat E., 2002). Textile industry wastewater causes significant challenges in conventional biological treatment plants that are highly sensitive to pH changes. Many dye compounds in the textile industry are either very difficult to biologically reduce or remain inert in conventional activated sludge systems commonly used for treating industrial wastewater. In cases where there are water-soluble basic, direct, and some azo dye wastes, microorganisms cannot biologically reduce these types of compounds, but they can adsorb some of the dye, thus affecting the color of the wastewater and achieving color removal (Kocaer F.O. and Alkan, 2002).**Membrane Use in Wastewater Recovery**To treat and reuse textile wastewater, all conventional and innovative methods ultimately converge on membrane processes. If the design of membrane processes is done correctly, it is possible to achieve results and efficiently reuse the treated water. However, even in a well-designed membrane process, it is essential to carefully consider concentrated flows and the problems they may cause. Therefore, the processes and units that will precede membrane systems must be very well designed. The most common problem encountered in membrane processes is the clogging of membranes and the selection of membranes that are not suitable for the content of the wastewater. For this purpose, frequently used MBR membrane bioreactors or combinations of UF (ultrafiltration) and RO (reverse osmosis) require careful calculation and use of many variables such as membrane material, pore size, hydraulic pressure, etc. Otherwise, you may end up with a system consisting of clogged membranes. In recent years, the decrease in membrane costs and the widespread use of membranes have...With the increasing use, we have gained much more field experience and knowledge. In light of this information, there is now much more knowledge available compared to the past regarding which wastewater should be treated with which pre-treatment or conventional system processes. It is beneficial to work in the light of this knowledge and experience while designing. Similarly, it is evident that previous experiences guide the emergence of new products. The durability of a membrane under harsh conditions, its response to temperature, pH, and pressure, as well as its sensitivity to various chemicals, is very important. Membranes selected under suitable conditions should also be financially self-sustaining in a well-functioning and well-operated treatment and recovery facility. In today's conditions, where water is scarce and naturally expensive, the recovery of water is ecologically very valuable and also noteworthy in terms of providing economic benefits.**Use of Ceramic Filters in Textile Wastewater**As the demand for the recovery of textile water increases, interest in ceramic membranes is also growing. In fact, it would not be wrong to consider the topic of ceramic membranes or ceramic filters as a miracle in wastewater recovery. This is because ceramic filters eliminate many of the problems encountered with other membrane filters. The pH resistance range is very wide, which both increases the scale of the wastewater to be treated and stabilizes the backwashing and filter cleaning processes. They also have considerable usage levels in terms of pressure and temperature. Again, they provide advantages over other alternatives in application and backwashing cleaning processes. They can offer very different options. In addition, they are strikingly superior in terms of durability and service life. Depending on the brand and model, their service lives can reach up to 15-20 years. They are extremely stable and useful systems that can eliminate the need for systems like sand filters and UF. By reducing the load of the systems used with them, they significantly decrease the total load of the system.It alleviates the burden. In recent years, with the production of high quality in our country, the initial investment cost has significantly decreased, making it easily applicable. It would be quite appropriate to say that it is unrivaled in terms of operating costs.**Is Wastewater Recovery Economical?**First of all, we must say that the concepts of being economical and ecological overlap completely. Every step that will be beneficial for the environment can be evaluated economically. Moreover, the fact that membrane costs have become quite cheaper compared to the past and that water is much more expensive than before indicates that there are also economic justifications for the recovery of wastewater.Such projects show that the investment can be recouped within 3-5 years in well-designed facilities. However, it is evident that necessary legal regulations must be made to encourage recovery. Taking more encouraging and compelling measures for recovery means better protection of both the environment and money.**References:**Asfour et al., Removal from Textile Effluents Using Hardwood Saw Dust and Adsorbent 1985

Baburşah S. Recovery and Reuse of Textile Industry Wastewaters Master's Thesis ITU 2004

Correıa et al., Characterisation of Textile Wastewaters, 1994

Delee W. et al., Anaerobic Treatment of Textile Effluents, Biotechnol 73, 32335. 1998

Erol E. Treatment of Wastewaters from the Cotton Textile Industry, Master's Thesis, KOU 2007

Kang & Chang, Coagulation of Textile Secondary Effluents With Fenton Reagent, Water Science and Technology 36(12) 215-222. 1997

Kocaer F.O. and Alkan U. Treatment Alternatives for Dye-Containing Textile Wastewaters Uludağ University Faculty of Engineering Architecture Journal Volume 7 Issue 1. 2002

Machenbach, I Membrane Technology for Dyehouse Effluent Treatment, Membrane Technology, 96, 7-11

Ölmez T. Color Removal from Reactive Dye Baths in the Textile Industry with Ozone, YLT ITU 1999

Pala A. and Tokat E. Color Removal from Cotton Textile Industry Wastewater in an Activated Sludge System with vVarious additives Water Research 36 2920-2925, 2002

**Chemical coagulation and biological treatment methods are the main treatment methods when the elimination of toxic substances from wastewater is ensured following pre-treatment processes. Textile wastewater can be classified as strong wastewater. Many dissolved inorganic solids in the wastewater require chemical treatment. Some organic solids that can be biologically decomposed also require biological treatment. The natural pH value of textile wastewater is between 9 and 13, and microorganisms can easily decompose wastewater with a pH value between 9 and 9.3.They can be treated biologically without the need for pH adjustment of textile wastewater in some cases. Even if textile wastewater is mixed with domestic wastewater, effective color removal cannot be achieved in conventional activated sludge systems. While the pre-treatment process effectively treats non-soluble disperse and vat dyes, it ensures the medium treatment of basic and direct dyes based on adsorption in activated sludge. However, the most commonly used reactive and acid dyes are treated very little. Another problem is the swelling phenomenon caused by nocardia and filamentous bacteria; although the complex structure of this phenomenon is not fully understood, high concentrations of starch and surfactants can cause it. The reason synthetic dyes, such as azo dyes, are resistant to microbial degradation under aerobic conditions is that they are synthesized in a way that prevents their colors from fading due to chemical and light-induced oxidative effects. Another factor that complicates the aerobic biodegradation, or biological degradation, of dyes is their high molecular weights, which make it very difficult for them to pass through biological cell membranes.**Anaerobic Treatment**The need for an external carbon source, such as glucose at approximately 2 g/l, in anaerobic biological treatment is a significant issue in practical applications. Additionally, operational difficulties generally hinder its widespread use in the industry, although its low cost may be considered in some cases. Like all steps in the treatment and recovery of textile industry waters, decisions should be made by evaluating all data and possibilities in the specific context of the local situation.**Sequential Aerobic – Anaerobic Systems**Anaerobic pre-treatment positively affects the removal of color, organic halogens, and heavy metals. With the feeding of wastewater with high color concentration to the activated sludge system following anaerobic treatment, 90% COD and 96% color removal can be achieved. In strong laundry wastewater containing organics such as oils and detergents, weakly biodegradable organics are removed at a high rate anaerobically.Following aerobic processes, advanced treatment methods such as sand filters and ultraviolet sterilization can enable reuse at rates of 30-40%. Additionally, better phosphate removal can be achieved by addressing foam and frothing issues. It is evident that using aerobic and anaerobic methods sequentially yields a higher treatment efficiency than using them individually. Evaluating this in terms of reuse is extremely important.**Fenton Reagent**In the Fenton process, Fe²⁺ ions are oxidized to Fe³⁺ ions while simultaneously H₂O₂ dissociates into hydroxide ions and hydroxyl radicals. These final products are used for effective organic matter oxidation. Generally, it is preferred to apply it in the pH range of 3-4 to ensure the solubility of iron. In terms of general categorization, the sequential application of chemical precipitation with Fenton reagents and activated sludge yields good results for textile wastewater. Although initial investment and energy costs are low, high chemical and sludge disposal costs arise. Sustainability should be considered during the design phase.**Electrocoagulation**In recent years, as interest and inclination towards the recovery of textile wastewater have increased, electrocoagulation is becoming more prominent as one of the treatment methods. So, what is electrocoagulation? Is it truly a method with a broad application field and a savior? Let's examine it.In this method, the formation of Fe(OH)₂ is effectively realized. This process occurs through the sorption on precipitated or floated iron or the reduction of azo dyes to arylamines in an Fe(II) environment. It is effective in COD and color removal. Its combined use with conventional methods can yield very good results. Particularly, its small footprint and integration into DAF systems are quite appealing. However, it should be noted that in high-flow waters, energy costs can be significant and there may be difficulties in changing plates. Additionally, points...Due to the principle of localized process creation based on a specific substrate, it should be considered that some waters may cover the surface of the plates and reduce electrical conductivity. In such cases, since the problem will be the wastewater itself, the electrocoagulation method should not be considered as the first option.**Photo Catalysis**By applying H2O2/TiO2/Fe3+ photocatalytic oxidation processes to biologically treated textile industry effluent, high COD removal can be achieved in addition to biological treatment. Although the investment and operating costs for the UV/H2O2 process are high, the chemical consumption is low. However, energy consumption is very high. Since UV transmittance has limits in certain dye characteristics, some studies have shown that the best use of UV technology is after ozone.**Ozonation**Ozonation, a method that has been mentioned in recent years for the recovery of textile wastewater, offers various options but also has some difficulties and limitations. Let's closely examine the method.The chemical oxidation method with ozone effectively removes color from textile industry wastewater. Since it is used in gas form, one of the most important advantages of ozone is that it does not increase the volume of wastewater and does not produce sludge. Another important feature of ozone is its ability to react with refractory substances, which cannot be biologically decomposed. However, the application of the chemical oxidation mechanism with ozone in textile industry wastewater aims more at removing color from the wastewater and increasing biological degradability than at COD removal. Ozonation of reactive dyes does not create a significant decrease in the total organic matter concentration of the wastewater. However, if its place in the overall process is well structured, it can play an important role in recovery.**Adsorption**Adsorption is utilized for the removal of biologically non-degradable dissolved organic substances. The most effective adsorbent is activated carbon. Activated carbon adsorption is the most effective method for color removal.One of the most common processes is the use of activated carbon, which is applied either as a final treatment after basic purification methods within a bed or as a powder in aeration basins. When applied as a final treatment, it helps in the removal of residual organic matter and color from waters that have undergone filtration. When added to the activated sludge system, it not only aids in color removal but also increases the organic matter removal efficiency of the activated sludge. However, due to the high cost of this material, recovery methods are required for its use. There are studies related to the treatment of reactive dyes with inorganic adsorbents. When synthetic clay is used as an inorganic adsorbent, some studies have shown that it can achieve a higher adsorption capacity than activated carbon under the same temperature and precipitation conditions. The use of biological adsorbents such as corn cob, rice husk, and wood has been observed to be more effective in the removal of basic dyes compared to acid dyes. The reason for this attraction to basic dyes is due to the coloumbic interaction between the negatively charged surface of the adsorbent and the positively charged ions of the dye. Since the use of basic dyes in the textile industry is not very common, the color removal using biological adsorbents remains limited. For the removal of reactive dyes found in textile dyeing wastewater, activated carbon adsorption, which has a high adsorption capacity, is the most suitable adsorbent. As a result, granular activated carbon adsorption is also an effective color removal method in dye wastewater.Today, the most commonly used biological treatment system is the activated sludge unit. In the activated sludge unit, the addition of powdered activated carbon has yielded very positive results in the treatment of substances that are difficult to remove, such as color, phenol, and cresol, in classical activated sludge systems. In this system, known as powdered activated carbon activated sludge, the addition of powdered activated carbon allows for the removal of toxic organic substances with low biological degradability without affecting the biological system, leading to an increase in system performance. Additionally, the residence time of the collected material within the system increases, facilitating its biodegradation by bacteria.However, due to the high cost of powdered activated carbon, the feasibility of powdered activated carbon-activated sludge systems is a topic of discussion. Finding cheaper adsorbents than powdered activated carbon will facilitate the development of these systems.**Combined Use of Adsorption and Ozone**The use of ozonation and granular activated carbon methods in a single process is considered a very attractive alternative to eliminate the disadvantages of both systems. Studies have also proven that the combined treatment process achieves efficiencies that standalone units cannot provide. Of course, it should be evaluated from the first step that both processes complement other processes and the suitability of the design according to the current situation.**Color Removal in Textile Wastewater**One of the most important parameters in the treatment and reuse of textile wastewater is color. Let's take a brief look at the literature to understand the formation and structure of color in textile wastewater.In the textile industry, dyeing is done to give color to the fabric. The characterization of dyed wastewaters is quite difficult due to the differences in the chemical structure of the dyes and the variability of the dyeing process. (Correia et al., 1994)Reactive and acid dyes that are brightly colored and soluble in water are considered the most problematic dyes from an environmental perspective because they are discharged without being affected by conventional treatment systems. It is known that the aerobic removal of these dyes in municipal treatment systems is insufficient. (Correia et al., 1994). Dyes generally show resistance to degradation under aerobic conditions. In traditional aerobic systems, the main removal mechanism is through the absorption by biological sludge. However, the adsorption of reactive dyes onto sludge is quite low, which causes issues related to the color problem in the discharge water. (Delee W. et al., 1998). Azo dyes can be decolorized under anaerobic conditions, with 75% COD and 99% color removal achieved for the red dye. In the case of the blue dye, 80% COD removal was achieved, and after 50 days of reactor operation, more than 90% color removal was obtained. Indigo dye containsIn a reactor, up to 95% color removal and up to 90% COD removal have been achieved (Manu B., Chaudhari S., 2003). While effective color removal from textile industry wastewater can be achieved by adding certain substances containing PAC and DEC to the Activated Sludge process, it has been observed in studies that effective color removal cannot be achieved with the addition of bentonite active clay, macrosorbents, etc. (Pala A. and Tokat E., 2002). Textile industry wastewater causes significant challenges in conventional biological treatment plants that are highly sensitive to pH changes. Many dye compounds in the textile industry are either very difficult to biologically reduce or remain inert in conventional activated sludge systems commonly used for treating industrial wastewater. In cases where there are water-soluble basic, direct, and some azo dye wastes, microorganisms cannot biologically reduce these types of compounds, but they can adsorb some of the dye, thus affecting the color of the wastewater and achieving color removal (Kocaer F.O. and Alkan, 2002).**Membrane Use in Wastewater Recovery**To treat and reuse textile wastewater, all conventional and innovative methods ultimately converge on membrane processes. If the design of membrane processes is done correctly, it is possible to achieve results and efficiently reuse the treated water. However, even in a well-designed membrane process, it is essential to carefully consider concentrated flows and the problems they may cause. Therefore, the processes and units that will precede membrane systems must be very well designed. The most common problem encountered in membrane processes is the clogging of membranes and the selection of membranes that are not suitable for the content of the wastewater. For this purpose, frequently used MBR membrane bioreactors or combinations of UF (ultrafiltration) and RO (reverse osmosis) require careful calculation and use of many variables such as membrane material, pore size, hydraulic pressure, etc. Otherwise, you may end up with a system consisting of clogged membranes. In recent years, the decrease in membrane costs and the widespread use of membranes have...With the increasing use, we have gained much more field experience and knowledge. In light of this information, there is now much more knowledge available compared to the past regarding which wastewater should be treated with which pre-treatment or conventional system processes. It is beneficial to work in the light of this knowledge and experience while designing. Similarly, it is evident that previous experiences guide the emergence of new products. The durability of a membrane under harsh conditions, its response to temperature, pH, and pressure, as well as its sensitivity to various chemicals, is very important. Membranes selected under suitable conditions should also be financially self-sustaining in a well-functioning and well-operated treatment and recovery facility. In today's conditions, where water is scarce and naturally expensive, the recovery of water is ecologically very valuable and also noteworthy in terms of providing economic benefits.**Use of Ceramic Filters in Textile Wastewater**As the demand for the recovery of textile water increases, interest in ceramic membranes is also growing. In fact, it would not be wrong to consider the topic of ceramic membranes or ceramic filters as a miracle in wastewater recovery. This is because ceramic filters eliminate many of the problems encountered with other membrane filters. The pH resistance range is very wide, which both increases the scale of the wastewater to be treated and stabilizes the backwashing and filter cleaning processes. They also have considerable usage levels in terms of pressure and temperature. Again, they provide advantages over other alternatives in application and backwashing cleaning processes. They can offer very different options. In addition, they are strikingly superior in terms of durability and service life. Depending on the brand and model, their service lives can reach up to 15-20 years. They are extremely stable and useful systems that can eliminate the need for systems like sand filters and UF. By reducing the load of the systems used with them, they significantly decrease the total load of the system.It alleviates the burden. In recent years, with the production of high quality in our country, the initial investment cost has significantly decreased, making it easily applicable. It would be quite appropriate to say that it is unrivaled in terms of operating costs.**Is Wastewater Recovery Economical?**First of all, we must say that the concepts of being economical and ecological overlap completely. Every step that will be beneficial for the environment can be evaluated economically. Moreover, the fact that membrane costs have become quite cheaper compared to the past and that water is much more expensive than before indicates that there are also economic justifications for the recovery of wastewater.Such projects show that the investment can be recouped within 3-5 years in well-designed facilities. However, it is evident that necessary legal regulations must be made to encourage recovery. Taking more encouraging and compelling measures for recovery means better protection of both the environment and money.**References:**Asfour et al., Removal from Textile Effluents Using Hardwood Saw Dust and Adsorbent 1985

Baburşah S. Recovery and Reuse of Textile Industry Wastewaters Master's Thesis ITU 2004

Correıa et al., Characterisation of Textile Wastewaters, 1994

Delee W. et al., Anaerobic Treatment of Textile Effluents, Biotechnol 73, 32335. 1998

Erol E. Treatment of Wastewaters from the Cotton Textile Industry, Master's Thesis, KOU 2007

Kang & Chang, Coagulation of Textile Secondary Effluents With Fenton Reagent, Water Science and Technology 36(12) 215-222. 1997

Kocaer F.O. and Alkan U. Treatment Alternatives for Dye-Containing Textile Wastewaters Uludağ University Faculty of Engineering Architecture Journal Volume 7 Issue 1. 2002

Machenbach, I Membrane Technology for Dyehouse Effluent Treatment, Membrane Technology, 96, 7-11

Ölmez T. Color Removal from Reactive Dye Baths in the Textile Industry with Ozone, YLT ITU 1999

Pala A. and Tokat E. Color Removal from Cotton Textile Industry Wastewater in an Activated Sludge System with vVarious additives Water Research 36 2920-2925, 2002

Şengül F. Properties and Treatment of Industrial Wastewaters Environmental Engineering Department publications no 172, DEÜ 1991