In the textile industry, where water consumption is high, it has become necessary to measure, monitor, and control the amount of water consumed in the facility through devices and automatic shut-off valves in order to reduce water consumption and prevent unconscious groundwater usage, along with the circular issued.

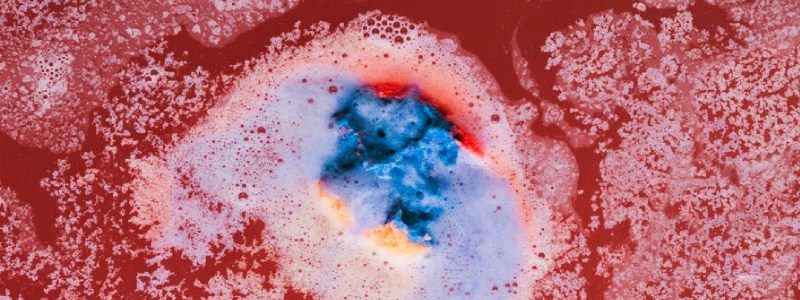

The Ministry of Environment, Urbanization and Climate Change published the "General Circular on Clean Production Practices in the Textile Sector" on January 29, 2023. Within the scope of this circular, efforts have been aimed at minimizing the negative environmental impacts of textile sector activities in 81 provinces, preventing air and water pollution, and implementing clean production technologies to reduce water and energy consumption. Particularly in the textile sector, which is intensive in water consumption, the necessity has arisen to measure, monitor, and control the amount of water consumed in the facility with flow devices and automatic shut-off valves in order to reduce water consumption and prevent unintentional groundwater consumption.**What is Clean Production?**The clean production mentioned in the circular aims to create processes that involve less water and chemical use during production, reduce solid waste and wastewater generated, and enhance energy efficiency, while also providing economic benefits alongside environmental sustainability, incorporating different elements for each producer.**The Necessity of Clean Production in the Textile Sector**Due to the significant destruction caused by decreasing natural resources and increasing environmental issues today, especially in developed countries, consumer sensitivity to the environment has increased, leading to a rising preference for products that cause less harm to the environment. At this point, the expectation of consumers in today's world is to minimize the harm to the environment during production while reaching the final product. Within the scope of the circular, the protection of diminishing natural resources and the minimization of harm to the environment have been targeted, as in the rest of the world. Particularly, the textile sector, which covers a large production area both globally and in our country, is one of the industries with the highest water consumption. Turkey's textile exports,In 2021, it increased by 31.0% compared to the previous year, reaching a level of 16.2 billion dollars, and with a 4.2% share of the world market, it rose to the 4th rank. In this sector, where our export potential is high, a large majority of the water used during production is supplied by underground water resources. Approximately 95-400 liters of water are used in the process applied to obtain 1 kg of textile product. Dyeing and finishing processes constitute a large portion of water usage in the textile industry, while high chemical consumption is also involved during these processes. The mixture of these chemicals with the water used leads to the formation of wastewater with high pollution levels. The resulting wastewater contains various pollutants such as color, heavy metals, phenols, surfactants, sulfur, inorganic salts, and high BOD, COD, and TSS. The discharge of such a wastewater containing various pollutants into the receiving environment inevitably brings many negative consequences, making treatment essential.However, the depletion of water resources, the lack of expected rainfall due to climate change, and the increase in drought and temperature clearly indicate that treatment alone is not sufficient. In our country, the treatment and reuse of wastewater in the textile industry have been clearly stated in a circular. At this point, increasing recycling/reuse along with clean production contributes to the conservation of natural resources by reducing production inputs such as raw materials, water, and energy, as well as the amount of waste generated.For years, as Artemis Treatment, we have shared this foresight with many of our customers and have implemented numerous projects that enable the recovery of textile wastewater, which is now deemed necessary, for reuse in production processes and for use in facility cleaning. It is clearly shown to us by nature that water recovery and reuse are necessary not only in the textile industry but also in many other industries.**What Are the Obligations Imposed on the Textile Industry with the Circular?**The circular aims to minimize the environmental damage caused by the textile sector's activities, prevent air and water pollution, and mandate the implementation of clean production technologies aimed at reducing water and energy consumption. Within the framework of the circular, textile companies are required to ensure the reuse of treated wastewater in possible areas, to separately collect cooling waters and wastewater with low pollutant loads as much as possible, and to ensure their reuse. In summary, without any capacity limits, all textile facilities that produce textile materials, perform textile pre-treatment, printing, and dyeing processes, as well as all textile facilities that carry out fabric mercerization are included;The wastewater generated in dyeing textile processes must be reused in fabric dyeing and washing as a result of necessary processes.

The brine solution used in water softening systems must be regenerated and reused in appropriate processes by removing its ions with the necessary technology.

Continuous hardness parameter control must be conducted in the water resulting from softening in water softening systems and in the washing water after regeneration to prevent the use of higher quality water than necessary.

The amount of water consumed during all production processes must be monitored specifically for the process, the total wastewater discharge rate must be continuously monitored, and a monitoring system must be established with records kept for these.

Regarding water and energy savings, treated wastewater must be used in appropriate places, cooling waters and wastewater with low pollutant loads must be separately collected and reused.

In continuously operating systems, flow-controlled and automatic shut-off valves must be used.

Chemicals must be distributed online through separate lines and distribution systems that mix them immediately before application must be used.

The caustic in the mercerization rinse water must be recovered with certain technologies or wastewater containing caustic must be reused in other pre-treatments.

Facilities located in organized industrial zones (OIZ) where water resources are limited must meet their water needs from the OIZ's wastewater treatment.The reuse of wastewater from facilities has been made mandatory.

The circular states the established capacity:In textile facilities with a capacity of 10 tons/day and above by January 15, 2024

In textile facilities with a capacity between 5 tons/day and 10 tons/day by January 15, 2025

In textile facilities with a capacity below 5 tons/day by January 15, 2026

it has been announced that the mentioned techniques will be implemented. At the same time, based on the air quality and water resources of the province where production takes place, the flexibility to advance these dates and determine lower threshold values with the decision of the Local Environmental Board has also been included in the circular.As a result of the published circular, necessary studies for the reuse of water have gained momentum for all textile facilities regardless of capacity. We may have consumed our natural resources without considering our future, but we can protect our existing resources with the right projects in expert hands before it is too late.**Sources**https://www.csb.gov.tr/tekstil-sektorunde-temiz-uretim-uygulamalari-genelgesi-yayimlandi-bakanlik-faaliyetleri-37401#

Öztürk, E., Hasanoğlu, P., Tanaçan, E., Özgür, C., Karaboyacı, M., Kitiş, M., 2015. “Assessment of Clean Production Potential in the Textile Sector”, National Environmental Engineering Congress, 2, 235-254.

Demirer, G. and Alkaya, E., 2018. “Guide to Clean Production in the Textile Sector”, WWF.

Dağlı, S., Duhbacı, T.B., Işık, E., Uyuşur, B., Partal, R., Keskin, B.A., Koç, D., Evren, M. and Akgül, M.K., Öztürk, E., 2018. “Guide to Resource Efficiency in Finishing Textile Products”, Republic of Turkey Ministry of Industry and Technology – TÜBİTAK MAM.

https://www.wwf.org.tr/ne_yapiyoruz/temiz_uretim/

https://ticaret.gov.tr/data/5b87000813b8761450e18d7b/Tekstil%20ve%20Hammaddeleri%20Raporu.pdf