The Fundamentals of Biological Treatment As is well known, in its most general definition, biological treatment is the process by which organic substances that cannot be removed through physical and chemical processes in wastewater are utilized by microorganisms as a source of nutrients and energy and are removed from the wastewater.

Biochemical processes ultimately convert organic matter into CO2 and H2O by microorganisms. In addition to organic matter, nutrients such as nitrogen and phosphorus are also removed in biological treatment.

Basic Objectives

To convert or oxidize biologically degradable organic matter in dissolved and particulate form into end products such as H2O, H2S, CO2, CH4,

To convert or capture non-degradable and suspended solids by floc,

To convert and remove nutrients such as nitrogen and phosphorus,

In some cases, to remove specific trace organic components and compounds.

These four basic objectives are generally applicable to domestic wastewater. The aim for industrial wastewater is to ensure the removal of organic or inorganic compounds. Since some of the compounds found in industrial wastewater are toxic to microorganisms, industrial wastewater must undergo pre-treatment before being discharged into the domestic sewage system.

Classical Activated Sludge Systems

The most commonly used method in biological treatment in the presence of oxygen is activated sludge systems. It is a treatment method where organic pollution is removed with the help of suspended microorganisms. Various modifications have been made in this process to solve different problems. Each modification has different criteria for its design.

Design of Classical Activated Sludge System

Selection of reactor type

Organic loading

Sludge production

Oxygen requirements and transfer

Nutrient requirements

Control of filamentous organisms

Characteristics of effluent water

Characteristics of Classical Activated Sludge System

The hydraulic retention time must meet the criteria of 30 minutes – 24 hours, and the volume of one or more reactor tanks should be such as to provide this hydraulic retention time.

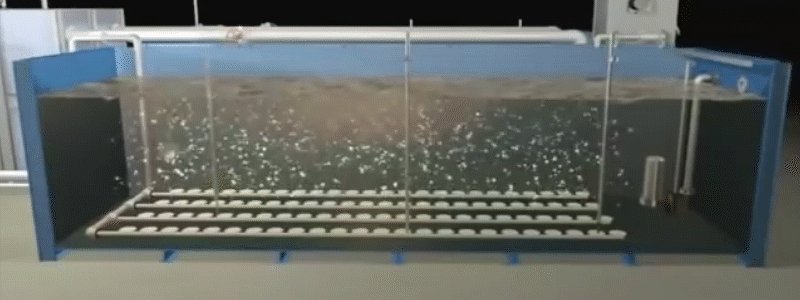

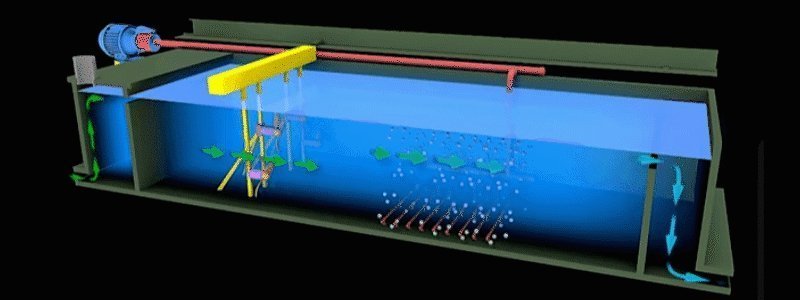

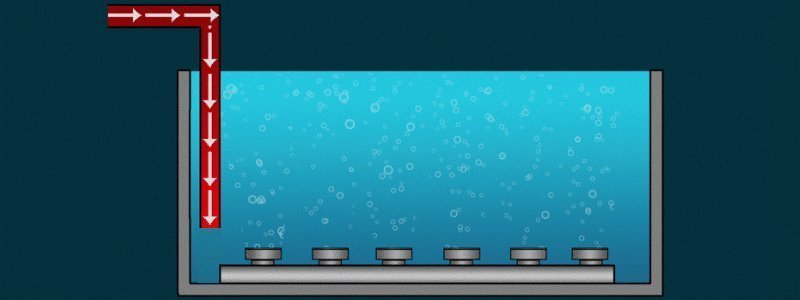

A diffuser is required to supply the necessary air.or or mechanical ventilation must be present.

There must be a system to ensure the mixing of wastewater within the reactor.

At the end of biological treatment, there must be a settling tank to separate the microbiological mass from the treated water.

The solids collected in the final settling must be returned to the beginning of biological treatment.

There must be a system for the disposal of excess biological solids.

The Role of Microorganisms

The dominant microorganism type becomes clear depending on the characteristics of the wastewater, environmental conditions, process design, and the way the process is operated. The efficient operation of an activated sludge process depends on the microorganisms' consumption of organic matter, their aggregation, settling to form concentrated sludge for recycling, and providing clear effluent water.

Microorganisms involved in biological treatment are classified as Eukaryotes, Eubacteria, and Archaebacteria, taking into account their cell structures and functions. Bacteria are single-celled prokaryotic organisms. They are quite commonly found in wastewater treatment units and are used for the removal of carbon, nitrogen, phosphorus, and sulfur compounds. The sizes of bacterial cells range from 0.5 to 3 µm and vary according to their shapes.

The Importance of Dissolved Oxygen

Dissolved oxygen (DO) is an important parameter in activated sludge systems. To ensure a continuous supply of oxygen in wastewater and to prevent oxygen limitation, the oxygen transfer rate must be greater than the oxygen consumption rate. The critical oxygen concentration is between 5-10% of the saturation concentration for bacteria and fungi (1-2 mg/l). To eliminate oxygen limitation in the environment, pure oxygen can be used, or the system can be operated under high pressure (2-3 atm).

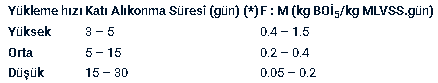

Required F/M Ratio and Solid Retention Time

Activated sludge processes, organic yHigh, medium, and low treatment speeds can be classified into three main groups.

(*) : Based on ventilation pool

The Role of Biological Treatment in Industrial Wastewater Treatment

In the treatment of industrial wastewater, biological treatment applications such as activated sludge systems, biofilm systems, stabilization ponds, aerated lagoons, and trickling filters are used. The activated sludge system consists of balancing, aeration, sedimentation, and disinfection units. Systems operating according to the activated sludge technique are the most commonly used systems in practice. The operation of stabilization ponds is simple and does not require much mechanical equipment, and they are grouped as aerobic, anaerobic, and facultative stabilization ponds. The necessary oxygen for aerated lagoons is supplied through diffusers or surface aerators. The anaerobic filter, developed as an adaptation of stationary cell reactors, provides the contact surface necessary for biofilm development using filling material in the form of an anaerobic filter. Fluidized bed systems; in this system, the upflow reactor is partially filled with a carrier material (usually sand). In the mentioned reactor, treatment is aimed to be carried out by forming a biofilm on the sand particles.

In conclusion..

Various biological treatment techniques are used in domestic and industrial wastewater treatment. Several parameters are effective in the biological treatment of these wastewaters, and these parameters must be within specified values. If the effective F/M ratio, the amount of dissolved oxygen, retention time, etc. parameters are chosen correctly, the treatment efficiency will be high. In this context, if your goal is to remove pollutants such as nitrogen, phosphorus, organic matter, particulate matter, etc. from your wastewater, biological treatment processes will be the right option for you.