Biogas is a renewable energy source that can be produced from the anaerobic treatment of biomass such as sewage sludge, municipal solid waste, agricultural waste, and animal waste.

Biogas consists of approximately 50-60% methane (CH4), 40-50% carbon dioxide (CO2), and small components such as hydrogen sulfide (H2S) and water. The use of biogas for energy production has recently gained significant attention due to its potential to replace fossil fuels, reduce greenhouse gas emissions, and decrease dependence on external energy sources.

The main sources that actually form the basis of biogas, which we see as waste in our environment, are as follows;

Agricultural product waste

Forest product waste,

Food and agricultural industry waste,

Domestic wastewater

Organic industrial wastewater

Organic portion of municipal solid waste and

Animal manures.

What Are the Advantages of Biogas?

Biogas is a renewable energy production process that should be preferred due to the increasing energy demand today, the desire to reduce environmental pollution caused by fossil fuels, and the recycling of waste. It has many advantages like these.

Energy is produced from organic waste materials, and they are returned to the soil.

It is a relatively inexpensive technology. It can also be used for electricity production and heating purposes. It is an environmentally friendly source of energy and fertilizer.

It enables waste recovery.

The use of animal waste as organic matter significantly reduces the odor of animal manure.

By using the gases produced in landfills as a form of energy, it also reduces the greenhouse effect.

It greatly minimizes the health risks and disease effects threatening human health and groundwater caused by animal manures.

How Is Biogas Produced?

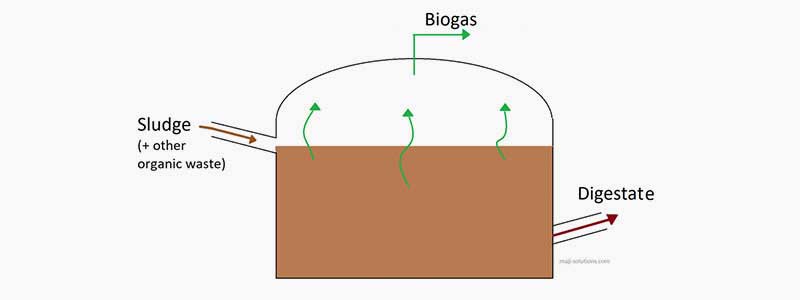

The fact that biogas is fundamentally an environmentally friendly application indicates that it should be preferred in every aspect. This eco-friendly approach arises from the anaerobic decomposition of the aforementioned wastes. Anaerobic decomposition occurs without oxygen and microorganisms.

The transformation of organic materials in the environment by microorganisms into other products. Anaerobic processes have been used for energy production from biomass in both developed and developing countries for years.The large-scale anaerobic processes used in biogas production are as follows:Fully mixed reactors,

Piston flow reactors,

Lagoon type reactors,

Centrigas system.

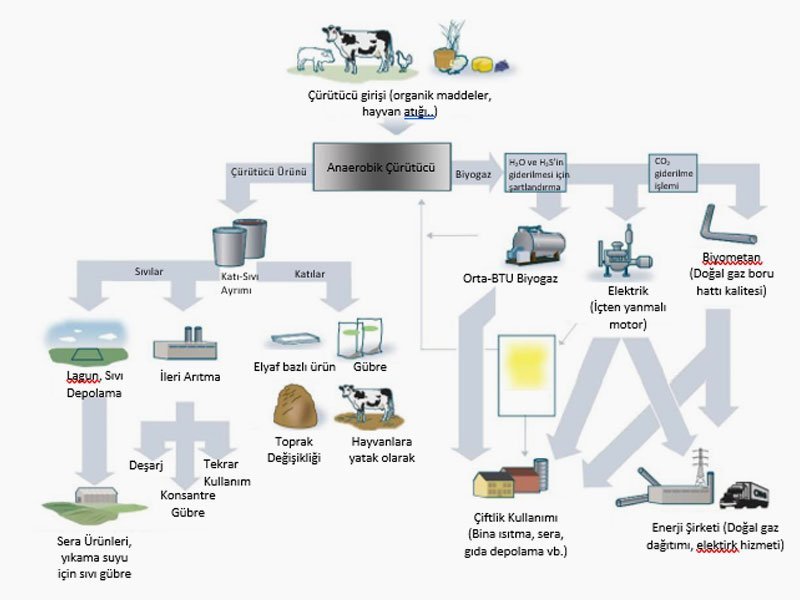

An example of a flow diagram for a complete biogas production facility is provided below.Organic waste arriving at the facility is taken to anaerobic reactors. The most basic outputs of these anaerobic reactors are biogas and fermented waste. The produced biogas is purified and used for the following purposes:Heating and warmth by direct combustion

Use as motor fuel for transportation

Electricity production by using it as turbine fuel

Use in fuel cells

Reducing costs by mixing with existing natural gas

Use of biogas during the production of chemical substancesOn the other hand, the fermented waste produced is our main topic. We know that the solid materials formed after anaerobic digestion are used as fertilizer. But what about the liquid part that is produced? Although it is used as fertilizer for field and greenhouse plants in some cases, the situation is not exactly like that. Many studies have emphasized in detail that this liquid part actually contains high pollution and needs to be treated with advanced purification technologies.**Why Should Anaerobic Reactor Effluents Be Treated?**The reactors mentioned above for biogas production also produce solid and liquid wastes in addition to biogas. These solid and liquid wastes can pass through a solid separator, where the solid part can be used as fertilizer, while part of the liquid waste is used as fertilizer for field or greenhouse plants, and the other part needs to undergo advanced treatment.The substances that come out of anaerobic reactors and are referred to as sludge or waste contain Nitrogen (N), Phosphorus (P), Potassium (K), and many trace elements.Due to its needle, it is a good source of plant nutrient elements and a good soil improver in terms of organic matter. When these wastes are dried, they are also evaluated as additives in animal feeds. However, since toxic substances that may be present in the materials fed to the fermenter will concentrate at the reactor outlet, analyses should be conducted before evaluating the materials coming from the reactors.The wastewater generated from the anaerobic process has high concentrations of nutrients, especially nitrogen, which are necessary for plant growth, along with high chemical oxygen demand (COD), biological oxygen demand (BOD), and suspended solids (SS), and it contains low dissolved oxygen (DO), making it unsuitable for direct discharge or application due to odor problems. It is potentially phytotoxic due to its high COD and low DO values. Additionally, the use of untreated anaerobic wastes can cause various human health issues, odor, and environmental pollution. During anaerobic digestion, a significant portion of organic nitrogen is converted to ammonia, which is phytotoxic if present in high concentrations. Dissolved ammonia is more toxic to plants than ammonium ions. If disposed of without treatment, the wastewater contains high levels of BOD, COD, and nutrients, which have the potential to pollute the environment.For these reasons, the liquid portion formed should be treated and monitored with necessary analyses. Indeed, according to Table 19 of the Water Pollution Control Regulation, there are discharge criteria. According to this table, the COD value of treated water should be 300 mg/l, the total Kjeldahl nitrogen (TKN) value should be 15 mg/l, and the suspended solids (SS) value should be 100 mg/l. In addition to these parameters, there are criteria for many other parameters as well. We are pleased to share our necessary experiences in reducing the burden of biogas facilities, which is an environmentally friendly approach, thanks to the advanced treatment technologies we apply at Artemis Treatment to meet these criteria.). “What is the most energy efficient route for biogas utilization: Heat, electricity or transport?”, Applied Energy, 206:1076-1087.

Ardıç, İ. and Taner, F. “Biogas Production from Biomass I: Fundamentals of Anaerobic Treatment”, Mersin University.

Saz, S., (2015). “Biomass Energy and Utilization Methods”, Graduation Thesis, Ondokuz Mayıs University, Samsun.

https://en.wikipedia.org/wiki/Anaerobic_digestion#Configuration

Krishnasamy, K., Nair, J. and Bauml, B., (2012). “Hydroponic system for the treatment of anaerobic liquid”, Water Science & Technology, 1164-1171.

Pehlivan, E. “Biogas and Biogas Applications”, Selçuk University, Konya.

Bachmann, N., (2015). “Sustainable biogas production in municipal wastewater treatment plants”, IEA Bioenergy.

Nkoa, R., (2014). “Agricultural benefits and environmental risks of soil fertilization with anaerobic digestates: a review”, Agronomy for Sustainable Development, 34(2):473-492.